- Order number: S10122

| Abmessungen | Artikel-Nr. | Preis | Menge |

|---|---|---|---|

| D=12 l=35 L=80 S=12 | S10122 | €82.52 * | |

| D=12 l=42 L=90 S=12 | S10122.1 | €87.20 * | |

| D=14 l=50 L=110 S=14 | S10122.2 | €137.40 * | |

| D=16 l=35 L=90 S=16 | S10122.4 | €153.69 * | |

| D=16 l=55 L=110 S=16 | S10122.3 | €170.16 * | |

| D=20 l=60 L=110 S=20 | S10122.5 | €194.59 * | |

| D=20 l=70 L=120 S=20 | S10122.6 | €211.40 * | |

| D=20 l=80 L=130 S=20 | S10122.7 | €243.04 * |

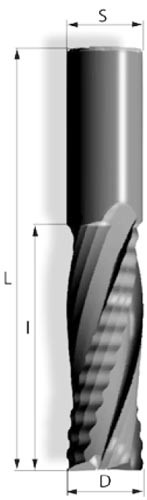

STC Solid Carbide Roughing Finishing Cutter 4 Flute Upcut, clockwise rotation, spiral groove

Solid carbide roughing finishing cutter 4 flute upcut is a spiral grooving cutter with 4 cutting edges for clockwise rotation. Of these, 2 cutting edges are produced with roughing teeth and 2 cutting edges are designed as finishing edges. These roughing finishing cutters 4 flute upcut are made of a new finest grain carbide. This solid tungsten carbide material makes it possible to produce very sharp cutting edges which remain sharp for a long time!

As with all upcut milling cutters, the better milling result is shown on the lower side of the machined workpiece. The chips are ejected upwards. The solid carbide 4Z roughing finishing cutter is suitable for cutting, copying and formatting solid wood, wood and board materials, laminate and plastics at high feed rates.

The advantages of the Solid Carbide Roughing Finishing Cutter 4 Flute Upcut:

The decisive advantage is the high productivity compared to other milling tools due to the increased wood removal rate. Finishing roughing cutters produce almost the same high-quality surfaces as finishing cutters, but with the outstanding performance of roughing cutters. The 2 cutting edges with roughing teeth enable high stock removal because they act as chip breakers. The 2 finishing edges then ensure the high surface quality of the finished workpiece.

Technical details of the Solid Carbide Roughing Finishing Cutter 4 Flute Upcut:

- D = Diameter of the roughing finishing cutter

- l = Working depth

- L = Total length

- S = Shaft diameter = D

- PWWU Article - No.: S10122

- Milling cutter type: four-edged, continuous cylindrical, positive spiral flute, upcut

- Material: finest grain solid carbide "premium quality"

- Shaft: cylindrical, smooth shaft according to DIN 1835 A.

- Design: four cutting edges, 2 rough cutting edges and 2 finishing edges.

- Application: solid carbide roughing-finish milling cutter for processing solid wood, wood and board materials.

- Machine: recommended for use in CNC machines equipped with appropriate chucks or adapters.

- Quality: from German production, exclusively manufactured for pwwu24.de by Präzisionswerkzeuge Wurzen

- Machining direction: basic and flank cutting. The face geometry with two center cutting edges enables drilling in

- Sustainability: the wide cutting edges allow multiple re-sharpening

- Protection: the tool is delivered safely in stable plastic packaging

Recommendations for use of the Solid Carbide Roughing Finishing Cutter 4 Flute Upcut:

If possible, we recommend plunge milling with a lateral process (plunge milling).

- Recommended speed range: n = 18000 - 24000 1/min

- Infeed per cutting edge: max. 0.1 mm

On request, the roughing finishing cutters can also be manufactured in special dimensions according to your specifications! This is inexpensive and fast.

- Do you have any questions concerning this product?

- Further products by PWWU Präzisionswerkzeuge Wurzen