- Order number: S10065

| Size | Artikel-Nr. | Preis | Menge |

|---|---|---|---|

| S10065 | €13.79 * | ||

| D= 3mm, l=12mm, L=60mm, S=6mm | S10065.1 | €24.04 * | |

| D= 3mm, l=12mm, L=60mm, S=8mm | S10065.2 | €29.24 * | |

| D= 4mm, l=15mm, L=50mm, S=4mm | S10065.3 | €15.53 * | |

| D= 4mm, l=15mm, L=60mm, S=6mm | S10065.4 | €24.04 * | |

| D= 4mm, l=15mm, L=60mm, S=8mm | S10065.5 | €29.24 * | |

| D= 5mm, l=17mm, L=50mm, S=5mm | S10065.6 | €18.90 * | |

| D= 5mm, l=17mm, L=60mm, S=6mm | S10065.7 | €24.04 * | |

| D= 5mm, l=17mm, L=60mm, S=8mm | S10065.8 | €29.24 * | |

| D= 6mm, l=22mm, L=70mm, S=6mm | S10065.9 | €25.42 * | |

| D= 6mm, l=22mm, L=70mm, S=8mm | S10065.10 | €31.35 * | |

| D= 7mm, l=32mm, L=80mm, S=8mm | S10065.11 | €33.45 * | |

| D= 8mm, l=22mm, L=70mm, S=8mm | S10065.12 | €31.35 * | |

| D= 8mm, l=32mm, L=80mm, S=8mm | S10065.13 | €33.45 * | |

| D= 9mm, l=32mm, L=80mm, S=12mm | S10065.14 | €70.50 * | |

| D=10mm, l=32mm, L=80mm, S=10mm | S10065.15 | €47.70 * | |

| D=10mm, l=32mm, L=80mm, S=12mm | S10065.17 | €70.50 * | |

| D=10mm, l=32mm, L=80mm, S=8mm | S10065.16 | €33.45 * | |

| D=10mm, l=42mm, L=90mm, S=10mm | S10065.18 | €50.83 * | |

| D=10mm, l=42mm, L=90mm, S=12mm | S10065.19 | €74.80 * | |

| D=12mm, l=35mm, L=80mm, S=12mm | S10065.20 | €70.50 * | |

| D=12mm, l=35mm, L=80mm, S=8mm | S10065.21 | €33.45 * | |

| D=12mm, l=42mm, L=90mm, S=12mm | S10065.22 | €74.80 * | |

| D=14mm, l=50mm, L=110mm, S=14mm | S10065.23 | €117.82 * | |

| D=16mm, l=35mm, L=90mm, S=16mm | S10065.24 | €131.79 * | |

| D=16mm, l=55mm, L=110mm, S=16mm | S10065.25 | €145.91 * | |

| D=20mm, l=60mm, L=120mm, S=20mm | S10065.26 | €216.98 * | |

| D=20mm, l=60mm, L=120mm, S=20mm | S10065.27 | €216.98 * |

|

|

|

|

|

|

|

|

|

|

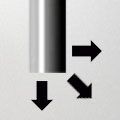

Solid carbide Finishing Cutter with 3 negative spirally grooved cutting edges for clean milling downcut.

Tripple-edged solid carbide Finishing Cutter for grooving, routing, copying or trimming

- hard wood, soft wood

- lightweight composite panels

- chipboards and MDF plain or melamine faced laminates decorative paper

- veneer

- duroplastics, thermoplastics

- compacts

- Trespa

- Corian and other solid surfaces

- GFRP (glass fibre reinforced plastics)

Suitable for portable routers, stationary routers and CNC milling machines.

The 3 negative spiral grooved cutting edges produce a lower cutting pressure than, for example, straight Finishing Cutters. The chip is ejected downwards. This shows the better milling result on the upper side of the workpiece. This Finishing Cutter thus produces particularly clean upper groove edges. This is important if the groove edges remain visible. The good side is at the top.

In contrast to the upcut end mills, the chips are not pulled upwards and are therefore poorly removed. The negative spiral groove of this end mill will tend to push the chips downwards. This means that milling with this spiral grooving cutter takes somewhat longer than with the positively grooved spiral grooving cutter. Since the chips are pressed downwards, the groove bottom is also not as clean as when milling with a positively twisted spiral groove cutter.

The face cutting edge geometry with three centre cutting edges designed with a plunging facility, so that this Solid Carbide Finishing Cutter can also be used for plunging.

Note for working with the portable router:

Hold your router firmly when milling, as the cutter blades tend to lift and push up the router during operation! When using these cutters, it is best to work with a milling table for the router. This end milling cutter type is well suited for professional use in large milling machines or CNC machining centres, wherever clean milling edges are required.

The feed rate should always be in the range between 8 - 13 m / min depending on the material.

This solid carbide Finishing Cutter is manufactured with a high balancing quality. Because only a carefully balanced milling tool works with the desired running smoothness.

Technical Notes about the Solid Carbide Finishing Cutters 3Z downcut:

- D = Diameter of cutting edges

- l = Length of cutting edges

- L = Total length

- S = diameter of the shank

- PWWU Order number: S10065

- Cutter type: Finishing cutter continuous cylindrical downcut

- Feed rate: 8 - 13 m / min

- Number of cutting edges: Z = 3, three -edged, 3Z

- Material: Solid Carbide (finest grain - STC, TC)

- Milling cutter face: with a plunging facility

- Shank design: Smooth shank (Shank with clamping surface available upon request).

- "Made in Germany" quality from German production

- Especially sustainable: wide cutting edges allow multiple regrinding

- Delivery in stable plastic box

On request, these Solid Carbide Finishing Cutters 3Z downcut can also be manufactured with special dimensions according to your special requirements! These Finishing Cutters are optionally available with a coating for higher wear resistance and longer tool life. However, coated milling cutters are not suitable for machining every material. We will be pleased to advise you.

- Do you have any questions concerning this product?

- Further products by PWWU Präzisionswerkzeuge Wurzen