- Order number: S10029.4

- EAN: 4056053290406

| Size | Artikel-Nr. | Preis | Menge |

|---|---|---|---|

| D=12mm, l=32mm, L=80mm, S= 8mm, downcut | S10029.2 | €94.82 * | |

| D=12mm, l=32mm, L=80mm, S= 8mm, upcut | S10029.4 | €95.20 * | |

| D=12mm, l=32mm, L=80mm, S=12mm, downcut | S10029.3 | €89.63 * | |

| D=12mm, l=32mm, L=80mm, S=12mm, up/down cut | S10029.5 | €99.16 * | |

| D=12mm, l=32mm, L=80mm, S=12mm, upcut | S10029.1 | €89.63 * | |

| D=12mm, l=32mm, L=90mm, S= 8mm, up/down cut | S10029.6 | €104.55 * |

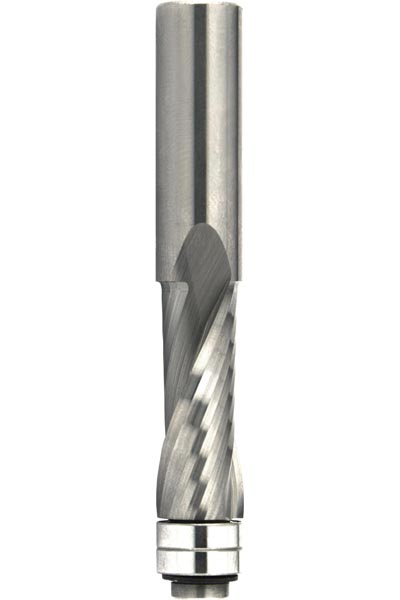

Solid Carbide Double - Bearing Spiral Flush Trim Bit with ball bearings / thrust rings Ø 12 x 32 x 80 mm

These Solid Carbide Double-Bearing Spiral Flush Trim Bits with two bearings Ø 12 x 32 x 80 mm are made of solid carbide. They are equipped with double bearings as thrust ring. Due to the two bearings, these cutters are also suitable for higher lateral pressure during flush milling. The spirally grooved cutting edges produce very clean milling edges. Less pressure can be applied to the workpiece.

(VHW Bündigfräser 2Z spiralgenutet mit Kugellager, VHW Frez do krawędzi 2Z z rowkami spiralnymi z łożyskiem kulkowym)

Solid Tungsten Carbide Double - Bearing Spiral Flush Trim Bits are used to adapt projecting workpieces that have not been milled through. STC copy milling cutters and Bearing Spiral Flush Trim Bits are also used for removing protruding edges or webs and for deburring residual material. This achieves a flat edge surface. The thrust ball bearing is guided centrally on the edge surface of the sample plate, while the cutting edges remove the protruding material. In these flush milling cutters with end face thrust rings, the cutting edges and thrust rings have the same diameter.

- Flush milling of plastic, wood or plywood.

- For copy milling with templates.

- The ball bearing is used as a stop.

Technical data: Solid Carbide Double - Bearing Spiral Flush Trim Bit Ø 12 x 32 x 80 mm

- Diameter: D

- Cutting edge length, working length: l

- Total tool length: L

- Shank diameter: S

- Milling cutter type: flush milling cutter, copy milling cutter

- Shank: cylindrical smooth according to DIN 1835 A.

- Cutting edges: double-edged, spiral, clockwise rotation.

- Quality from German production, exclusively produced for pwwu24.de by Präzisionswerkzeuge Wurzen

Upcut: Solid Carbide Double - Bearing Spiral Flush Trim Bit with ball bearings / thrust ring

- Direction of twist: positive, right

- Direction of rotation: clockwise

- Direction of chip ejection: upwards

|

S10029.4 |

S10029.1 |

The chip ejection with this variant is carried out upwards. The better surface of the milled workpiece edge is shown on the lower side of the machined workpiece. This is because the chips are moved upwards by the twisted cutting edges, i.e. away from the lower edge of the workpiece.

Downcut: Solid Carbide Double - Bearing Spiral Flush Trim Bit with ball bearings / thrust rings

- Direction of twist: negative, left

- Direction of rotation: clockwise

- Direction of chip ejection: downwards.

|

S10029.2 |

S10029.3 |

The chip ejection in this variant is downwards. This means that the smoother surface of the milled workpiece edge is visible on the upper side of the machined workpiece, since the chips are moved downwards by the twisted cutting edges, i.e. away from the upper workpiece edge.

Up / Down cut: Solid Carbide Double - Bearing Spiral Flush Trim Bit with ball bearing / thrust ring

- Direction of twist: negative, left + positive, right

- Direction of rotation: clockwise

- Direction of chip ejection: to the center of the workpiece.

The chip ejection with this variant takes place in the middle of the workpiece. Both milled workpiece edges have clean cutting edges. The chips on the upper side of the workpiece are guided downwards by the right-hand twisted cutting edges. The chips on the lower side of the workpiece are guided upwards by the left-hand twisted cutting edges.

- Do you have any questions concerning this product?

- Further products by PWWU Präzisionswerkzeuge Wurzen

Präzise Ausführung , beste Schnitthaltigkeit!

Wie schon zuvor schnelle Lieferung, sehr präzise Ausführung des Fräsers, beste Schnitthaltigkeit auch in harten Werkstoffen und absolut exzelente Kaufabwicklung sowie Kommunikation! Sehr gern werde ich wieder bei pwwu24 einkaufen!!! Vielen Dank:-)

Der Bündigfräser ist sehr gut verarbeitet und schneidet perfekt.

Der Bündigfräser macht eine sehr saubere Oberfläche, ist schön scharf und macht guten Spanabtrag. Ich benutze den Fräser jetzt häufiger als erwartet, weil keine aufwendigen Vorrichtungen zur Führung mehr erforderlich sind.