- Order number: S1037.070

| Abrasive Grit Hardness | Artikel-Nr. | Preis | Menge |

|---|---|---|---|

| EK 40 K | S1018.42 | €22.05 * | |

| NK 20 M | S1037.076 | €18.02 * | |

| NK 25 Jot | S1037.072 | €17.52 * | |

| NK 25 M | S1037.108 | €18.02 * | |

| NK 32 K | S1037.082 | €18.02 * | |

| NK 32 N | S1018.422 | €18.02 * | |

| NK 40 O | S1037.070 | €17.59 * | |

| NK 70 M | S1037.106 | €18.02 * |

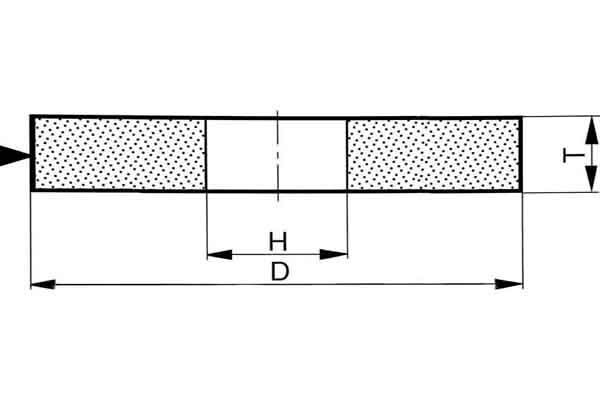

Grinding wheel Ø = 200 x 25 x 32 mm for use on bench grinders or grinding machines

Possible applications: Grinding wheels with Ø = 200 x 25 x 32 mm are suitable for use on bench grinders or other grinding machines with a corresponding holder.

Technical data grinding wheel Ø = 200 x 25 x 32 mm:

|

|

Which abrasives are available?

NK - Normal corundum: For simple grinding work with the bench grinder, for roughing iron and not too hard steel, for cast steel or crucible steel castings.

EK - Aluminium oxide: Recommended for grinding materials with high tensile strength, such as stainless steel, hardened steels like tool steel or high-speed steel, but also for some high-tensile aluminium and bronze alloys.

SiC - Silicon Carbide: Silicon carbide is harder than normal corundum or noble corundum. Silicon carbide has a sharper grain shape. It is a very versatile abrasive that can be used for grinding relatively soft metals such as aluminium or cast iron as well as extremely hard materials such as hard metal.

What grit do I need?

A medium or coarse grit is recommended when surface quality is less important. The coarser the grit, the faster the material removal. Therefore, coarser grits are more suitable for large contact areas than fine grit sanding discs. They are also the better choice for soft, tensile and tough materials such as mild steel and aluminium.

A fine grit is useful when a better surface finish is important. Finer grits should also be used for smaller contact areas. When working on hard and brittle materials such as glass, tool steel and carbide, fine grit abrasives are more suitable.

|

|

|||||||||||||||||||||||||||||||||||||||

Which hardness is right for my application?

Hardness is used to indicate the relative holding forces of the bond that holds the abrasive grains together in a disc.

Low hardness:

- For hard materials such as hardened steels, hardened tool steels or high-speed steel.

- For large contact areas

- For higher material removal

High hardness:

- For softer materials

- For smaller or narrow contact surfaces

- For longer wheel life

Workshop - stock sale: The grinding wheels come directly from the workshop stock and may therefore show discolouration or slight soiling due to storage, but this does not affect their usability.

These grinding wheels Ø = 200x25x32mm are only in stock in the quantity that can be ordered above. Delivery of this sale item is therefore only possible while stocks last.

- Do you have any questions concerning this product?

- Das richtige Aufspannen von Schleifkörpern und die Klangprobe

- Further products by Schleifkörper